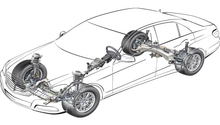

Mercedes-Benz E-Class and E-Class AMG: Why is My Suspension Making Noise?

Nothing can ruin luxury more than a noisy suspension. Here's how to diagnose the issue and get your Mercedes-Benz E-Class screaming luxury again.

This article applies to the Mercedes-Benz E-Class and E-Class AMG (2002-2009).

The Mercedes-Benz E-Class is known for having an exceptionally composed ride-quality. Noise means that there are components in the suspension that have been worn down and are in need of replacement. Best case scenario it might be something like a sway bar bushing that is old or in need of grease. If a little grease is what it needs, then the problem can be fixed with a blast of WD-40. However, squeals, pops and clunks are symptoms of failing joints. Here's how to diagnose the problem.

Materials Needed

- Jack stands

- Tire iron

Step 1 – Examine anti-rollbar bushings and endlinks

Typically, noise from the suspension is the result of a worn bushing or joint. The best way to tell if they're in need of replacing is to crawl into the wheel well and look at the rubber bits in the sway bar end-links. If they're cracked and crumbly, they should be replaced. If there is no rubber and the sway bar is meeting metal to metal (look for shiny spots on what should be otherwise dirty parts), it should be replaced immediately.

The bushings on the sway bar might also be worn out or dry. This is a far less serious issue, but the squeaking of the bar moving around in the bushing can be annoying. Replacing them is inexpensive and can be done at home with simple hand tools.

(Related Discussion: Stabilizer Bushings and Endlinks - MBWorld.org).

Step 2 – Check upper and lower ball joints for play

The easiest way the check if the problem is the ball joints is by looking at the joint itself. If the rubber boots around the top or bottom ball joints are torn at all, those joints will be worn out and in need of replacement. The rubber boots should be filled with grease that will keep them operating smoothly. If it's warped or ripped, the joints will have no lubrication and wear out. The other way to test is by checking the ball joints for vertical play. To do this, lift the end of the car that's making the noise and put it on jack stands. With the wheel in the air, apply force to the bottom of the wheel with a pry bar or something similar, the idea is to simulate the wheel going over a bump. As you do this, watch the bottom ball joint and the top ball joint. If there's slack, meaning the wheel moves up and down without the control arm moving up and down in sync, the joint needs to be replaced. The w211 E-Class has two lower ball joints and one upper ball joint.

(Related Article: How to Replace Ball Joints - MBWorld.org).

Step 3 – Tie-rod ends

A less common cause of suspension noise is worn out tie-rod ends. Should this rubber cover ripple, tear, or otherwise deteriorate, the joint will quickly breakdown. Commonly, a worn tie-rod can be diagnosed by lifting the front end of the car, grabbing the wheel in the 3 and 9 o'clock position, and jiggling it hard. If the wheel moves back and forth at all, the tie-rod ends are worn out and need to be replaced. Typically this will also be accompanied by a vague steering feel.

(Related Discussion: Easy Tie-Rod End Test - mbworld.org).

Step 4 – Subframe bolts

The tell tale noise for the subframe coming loose is a clunk coming from the rear end while driving over bumps. Also, unlike other suspension issues a subframe that's loose will feel like the entire rear end shifts around instead of a localized movement. There is no easy way to check this at home, so your best bet is to take it to a trusted mechanic. The parts are typically inexpensive, but the labor is intensive.

Figure 5. Rear subframe bolt.

(Related Article: Subframe Bolts - MBWorld.org).

Step 5 – Airmatic shocks

If you're driving a w211 equipped with airmatic suspension, a clunking noise from the shock absorbers is one of the first signs something has gone wrong. A failure in the airmatic system typically triggers a light on the dash board, but a partial failure might result in noise without a warning. Visually check the wheel that's clunking for pit marks and tears in the airbag. If you're unsure of what to look for, it is a good idea to take it to a shop. Replacing the shock itself isn't a difficult task for the average DIY mechanic.

Pro Tip

If this is your problem, it's recommended to buy the parts from Airnott instead of Mercedes. The quality is standard and the price is only half as much.compared to the OEM Mercedes-Benz option.

Featured Video: Balljoint Test Example

Related Discussion

- Front Suspension Clunk - MBWorld.org