Mercedes-Benz C-Class: Why is My Brake Pedal Soft?

Your braking system uses fluid pressure to create friction between your brake pads and rotors, slowing down your vehicle. If your brake pedal does not maintain a firm and responsive feeling, a problem is present and your vehicle may not stop in a safe amount of time.

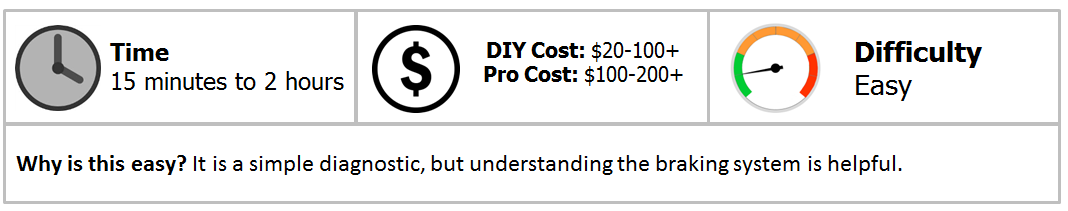

This article applies to the Mercedes-Benz C-Class w204 (2007-2014).

When you press down on the brake pedal, normally your Mercedes comes to a complete stop in a smooth manner with relatively minimal effort on your part. The brake pedal is attached to a rod that connects to the master cylinder. On top of the master cylinder is a reservoir containing the brake fluid. When the master cylinder compresses from the brake pedal rod movement, fluid runs through the brake lines to the brake calipers. Inside of the calipers is a piston that applies pressure to the brake pads. When the pads contact the rotors, which move with the wheels, your vehicle begins to slow down.

When air, dirt, as well as moisture mix with brake fluid, the fluid becomes compressible and creates a soft brake pedal. Not only does dirt inside the system create problems, but dirt can create rust and corrosion on the brake lines routed to each wheel. Moving parts in use with the brake system wear as well. The master cylinder and brake caliper both contain rubber seals that keep the fluid compressed. When a caliper has a seal failure, it may apply against the brake pad unevenly, creating uneven wear and improper pedal feel.

Materials Needed

- Gloves

- Safety glasses

- STAR diagnostic tool (if needed)

- Pressure bleeder (if needed)

The steps are listed from most likely to occur to least likely.

Step 1 – Air is mixing with the brake fluid

Air compresses in place of the non-compressible brake fluid, creating a soft brake pedal.

Air can mix with the brake fluid for a number of reasons:

- The fluid level may be low. When the brake pedal is pushed, the master cylinder creates a suction inside of the reservoir to keep the optimum amount of brake fluid inside the lines. If no fluid is present, air will be drawn inside of the lines instead.

- Air can enter through an opening in a rubber seal around a caliper piston, or a junction in a brake line. This is usually accompanied by a fluid leak and a low fluid level.

An easy way to check for air in your system is with two people, and removing the reservoir cap to pump your brake pedal ten times. Hold the pedal down at the tenth pump, and then release while watching the fluid in the reservoir for a disturbance. If the fluid returning back into the master cylinder creates a large disturbance, air is present in the system.

Step 2 – Brake fluid is leaking

Brake fluid can leak out of the many connections made between lines, the abs module, the master cylinder, and the calipers. If corrosion on brake lines is left untreated, the lines can rupture. Fluid may also leak from the caliper piston seals.

Between the steel brake lines and brake calipers are rubber lines installed to allow suspension movement. Corrosion and prolonged wear can create weak areas in the rubber that swell under pressure, keeping the fluid from being compressed adequately.

The Mercedes C-Class w204 has a screen in the center of the gauge cluster that will display a "low brake fluid level message." If you find your brake fluid level continuously dropping after filling the reservoir, there is a leak somewhere in the system. Park the vehicle and pump the brake pedal several times. Then hold the pedal down for several seconds. Looking under the vehicle and around the wheels you should be able to spot the leak's location.

Step 3 – The brake fluid may be contaminated

Brake fluid is hygroscopic, meaning it absorbs moisture. When moisture enters the system, the fluids boiling point lowers. Under heavy braking heat it will create air bubbles and cause a soft brake pedal.

Dirt present in the system will increase wear to components like the master cylinder, calipers, and abs module.

The fluid should not be dark in color. Pour some fluid onto a paper towel and inspect the towel for dirt. Be sure to wear protective gloves because brake fluid is harmful to your health.

Step 4 – A problem with your brake pads and/or piston calipers

If the caliper piston does not apply evenly, uneven wear will take place on the piston face and brake pads. A tapered brake pad will create a soft pedal by initially applying only one side of the pads against the rotors.

Brake pads can also become brittle and crack after prolonged use. As the pad compresses, it spreads apart and cannot generate a consistent amount of friction.

The caliper piston may also have a damaged seal or damage to the walls of the piston bore. This may cause the piston to apply or retract slowly.

Step 5 – An internally leaking master cylinder

The master cylinder contains rubber seals that maintain fluid pressure while the brake pedal is being applied. If one of these seals was to tear or move out of its correct position, fluid will bypass the seal and result in a loss of pressure. This condition will be accompanied by a brake pedal that is soft and slowly sinks towards the floor.

Step 6 – Improperly bleeding the brakes

If the correct procedure is not followed while bleeding the brakes, air can remain trapped inside the system. The braking system on your Mercedes includes ABS/DSC (anti-lock braking and dynamic stability control) valves that should be actuated while performing the procedure. The correct way to do this is by using the STAR diagnostic tool and actuating them through bi-directional control.

Mercedes also advises using a pressure bleeder. This unit attaches to the fluid reservoir and uses compressed air to force the air mixed with fluid out of the bleed screws.

Step 7 – A bad wheel bearing

A bad wheel bearing can cause rotor movement, which increases the distance the caliper piston must expand to compress the brake pads.

Mercedes has been known to install sliding caliper systems on there non-sport models. Generally, the single piston calipers are of the sliding type.

Symptoms of a bad wheel bearing include:

- Knocking, clunking, or grinding noises. These may be more prevalent during stop and go, or while making turns.

- Humming, rumbling or growling noises. These tend to be noticeable while driving straight, but the pitch may increase while turning.

- Vibration in the steering wheel. This may indicate mechanical damage to the wheel bearing.

Figure 7. A single piston brake caliper.

Figure 8. Two wheel bearings.

Related Discussions

- Mushy Brake Pedal After Pad Replacement - MBWorld.org

- C63 Soft Brake Pedal - MBWorld.org

- Installed Pads, Now Soft Pedal - MBWorld.org